Rating ........................................................................................................................................................................... P1

Rated power-kW ................................................................................................................................................... 176

Rated speed-rpm ................................................................................................................................................. 1800

Overload power-kW ........................................................................................................................................... 194

Overload speed-rpm ......................................................................................................................................... 1858

Rated power tolerance-% .............................................................................................................................. ±3

Low i dle speed rpm .......................................................................................................................................... 650

High idle speed rpm .......................................................................................................................................... 1980

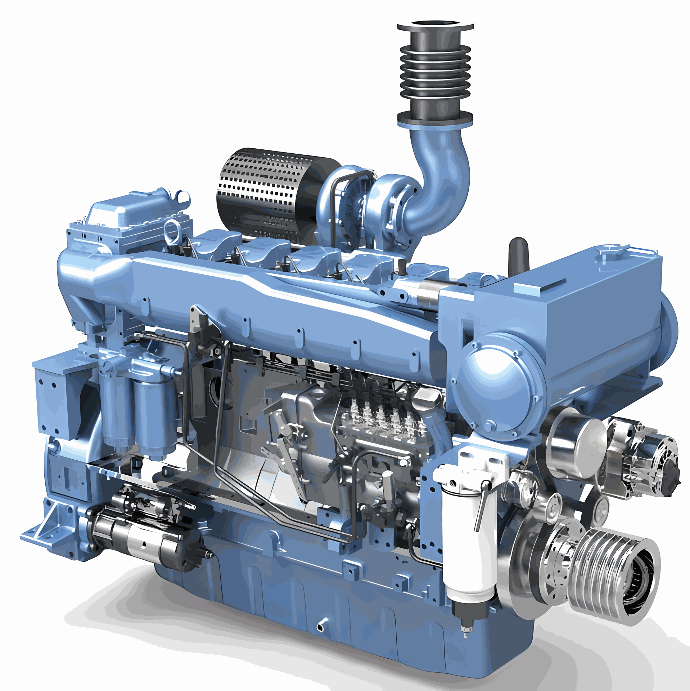

No of Cylinders / Valves ................................................................................................................................. 6/12

Cylinders arrangement .................................................................................................................................... In line

Thermodynamic cycle ...................................................................................................................................... 4 stroke

Bore × Stroke-mm(in) ......................................................................................................................................... 126×130 4.96×5.12

Compression ratio ................................................................................................................................................ 17:1

Displacement-L(in 3 ........................................................................................................................................... 9.726 593.5

Fuel system ............................................................................................................................................................... Mechanical

Injection system ..................................................................................................................................................... Direct injection

Aspiration .................................................................................................................................................................... Turbocharged and aftercooled

Flywheel housing/Flywheel/N° of teeth on flywheel ring gear(standard) .............. SAE 1/14"/136

Flywheel housing/Flywheel/N° of teeth on flywheel ring gear(optional) ................ /

Firing order ................................................................................................................................................................. 1 5 3 6 2 4

Rotation(from flywheel end) ......................................................................................................................... Counterclockwise

Overall dimensions (L×W×H mm(in) ........................................................................................................ 1532×814×1076 60.3×32.0×42.4

Dry weight-kg(lb) ................................................................................................................................................... 1056 2328

Wet weight-kg(lb) .................................................................................................................................................. 1151 2537

Max. output power of front end-kW( Ps ............................................................................................... 92.96 126.4

Emission compliance .......................................................................................................................................... IMO Tier II

Lifting cylinder height m(ft) ............................................................................................................................ 1 3.28

Continuous Duty (P1)

The engine can run at full load continuously. The average load factor is 70% to 100%. An nual working time is recommended but not limited to 5000h-8000h

Heavy Duty (P2)

The engine can run at full load for 8h every 12h. The average load factor is 40% to 80%. Annual working time is recommended but not limited to 5000h.

Intermittent Duty (P3)

The engine can run at full load for 4h every 12h. The average load factor is 40% to 80%. Annual working time is recommended but not limited to 3000h

Light Duty (P4)

The engine can run at full load for 2h every 8h. The average load factor is about 60%. An nual working time is recommended but not limited to 1000h.

High Performance Duty(P5)

The engine can run at full load for 0.5h every 5h. The average load factor is about 60%. Annual working time is recommended but not limited to 500h.